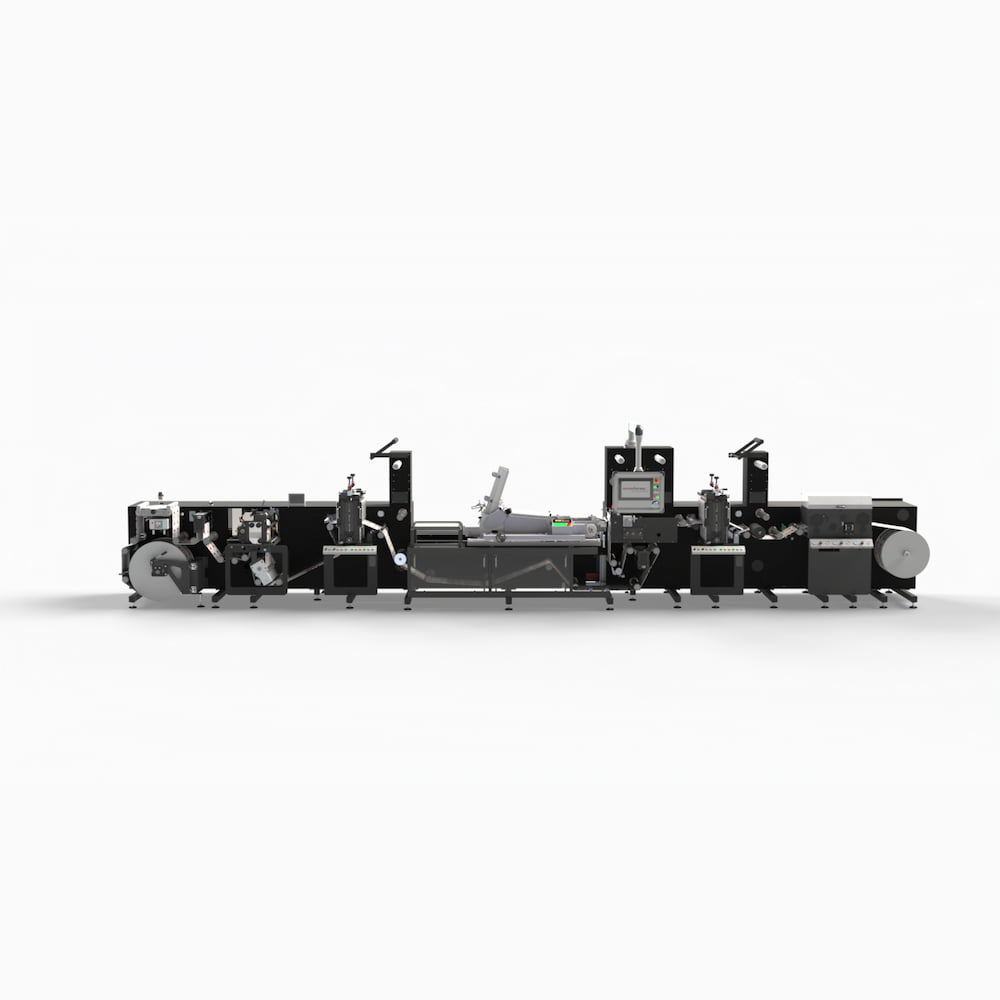

Features

Standard Configuration Includes:

- Compact and robust design

- 15 inch touch screen panel on separate HMI console

- 100% servo control from Bosch Rexroth

- Job memory for 500 jobs

- Remote diagnostics

- Unwind unit

- Splice table at unwind

- Static buffer

- Vertical inspection area

- Web guide before the slitting unit

- Cartridge slitting system including LED light

- Label/length counting

- Single rewind – 76 mm (3”) core holder

- Right to left configuration only