Features

- Increased Productivity

- Reduced Waste

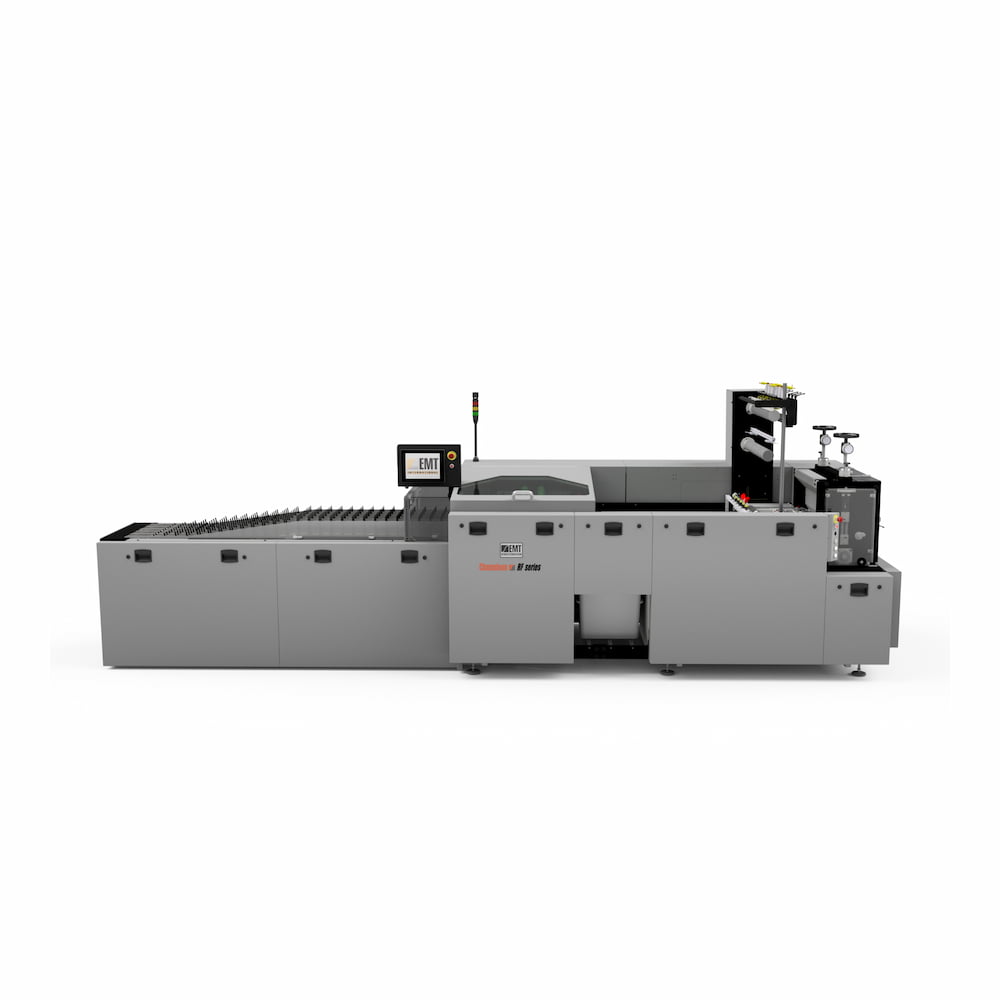

The innovative configuration includes:

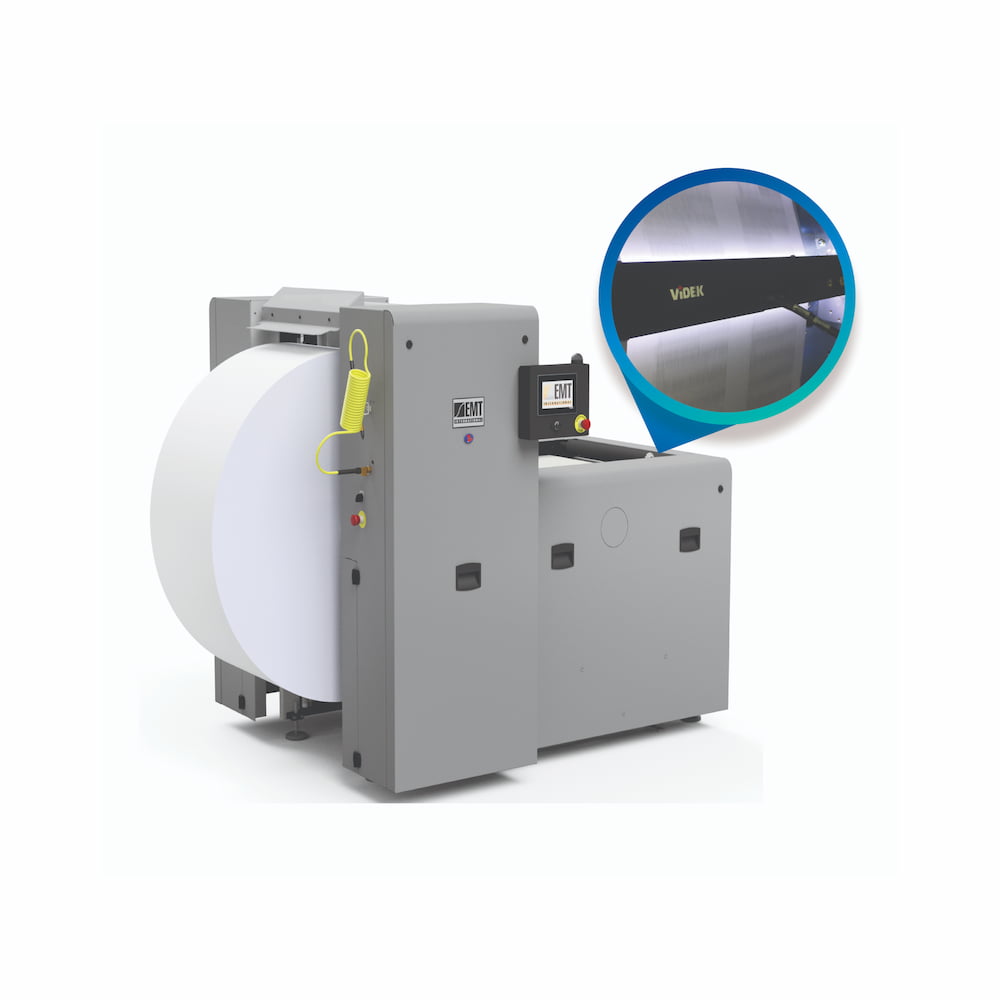

- Unwind and Web Handling Systems

- Pre-cut

- Each lane:

- Lane formats create family of sizes

- Dedicated x-perf unit to create a pre-cut at tail of the photo

- Offcut remains attached to waste matrix at sides and tail

- Functions similarly to a rotary die cutter

- Registration – TOF mark

- Bar code controlled – on back or in trim

- Each lane:

- Gap Creation

- Separates orders in each lane and prepares them for delivery

- Each lane behaves independently

- Stream of products

- Shingled with very small reveal

- Accelerator belt

- Advances between end of order and start of next order

- Creates larger reveal between orders

- Shingle position adjustment

- Required for format length at changeover

- Die Cutting

- Combines removal of all waste with cut process

- Die-cut pattern: Separates finished products from the matrix of waste (gutter and chip) which remains as a web

- Precut offcuts: Removed

- Waste matrix: pulled away to either be rewound by the matrix rewind or collected by an evacuation system

- Separation Module

- Comprised of two sets of straight and angled vacuum belts that selectively diverge the streams family of finished products go straight through the separation module

- Other products are diverged with the angled belts

- Pocketer Delivery

- Pocketer: flighted conveyor that collects completed orders

- Finished products transported through the gap creation section and fill a pocket

- When order is completed

- Gap creation section pauses, conveyor indexes to the next pocket

- Each lane is independent

- Finished orders collected by operators after they are delivered by a pocket