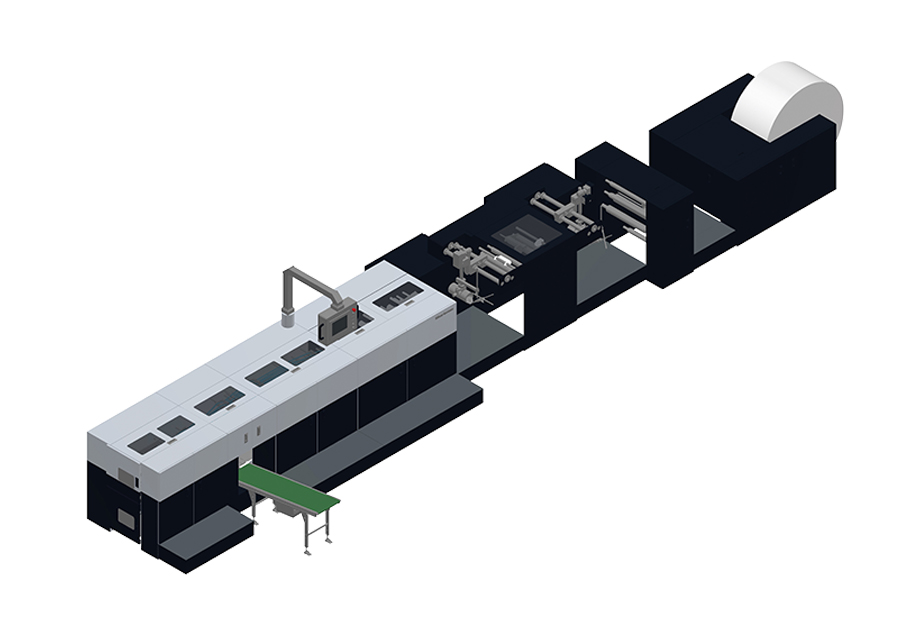

COMPACT YET ROBUST – The BBS-56 features a footprint that is smaller than conventional plow folds for operational convenience without sacrificing production power.

AUTOMATIC SPEED OPTIMIZATION – Once the production speed is input into the control panel, the BBS-56 will automatically adjust the unwinding speed during production to match that speed to increase productivity even when processing variable page count book blocks. This is accomplished by scanning barcodes with sheet count information that is printed on each sheet.

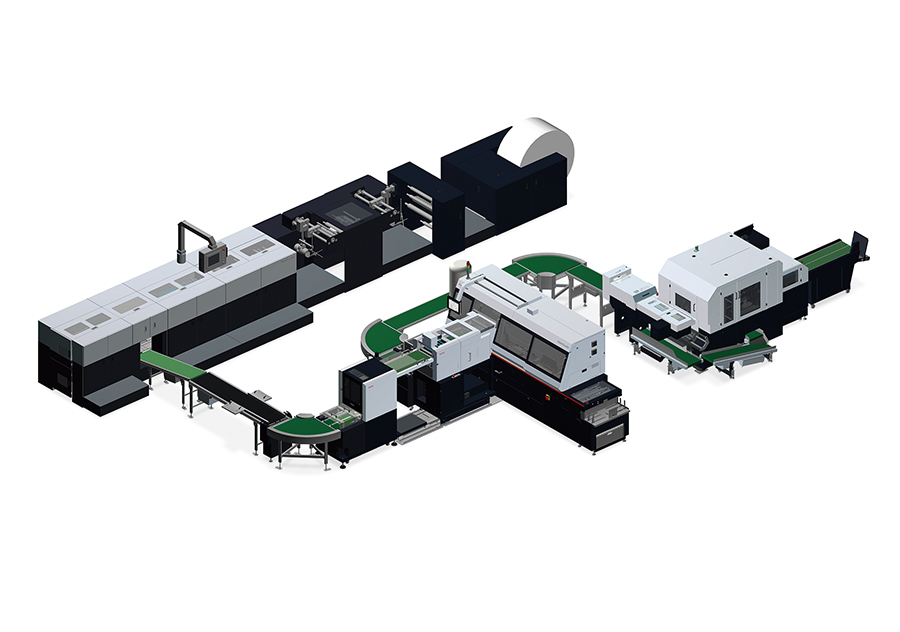

SYSTEM CONNECTIVITY – The BBS-56 is the perfect match for inline integration with our flagship solutions, the iCE BINDER BQ-500 and 3-knife trimmer HT-1000V, because of similar production speeds. As the BQ-500 and HT-1000V excel in variable thickness book production, it's possible for them to produce books of differing thicknesses received from the BBS-56 without stopping for changeovers.

| Model | BBS-56 |

|---|---|

| Roll Size | Roll Paper Width : Max. 584.2 mm or 23.00” Min. 218.0 mm or 8.60” Roll Outer Diameter : Max. 1,270 mm or 50” Min. 150 mm or 5.91” Roll Weight : Max. 750 kg or 1,652.0 lb |

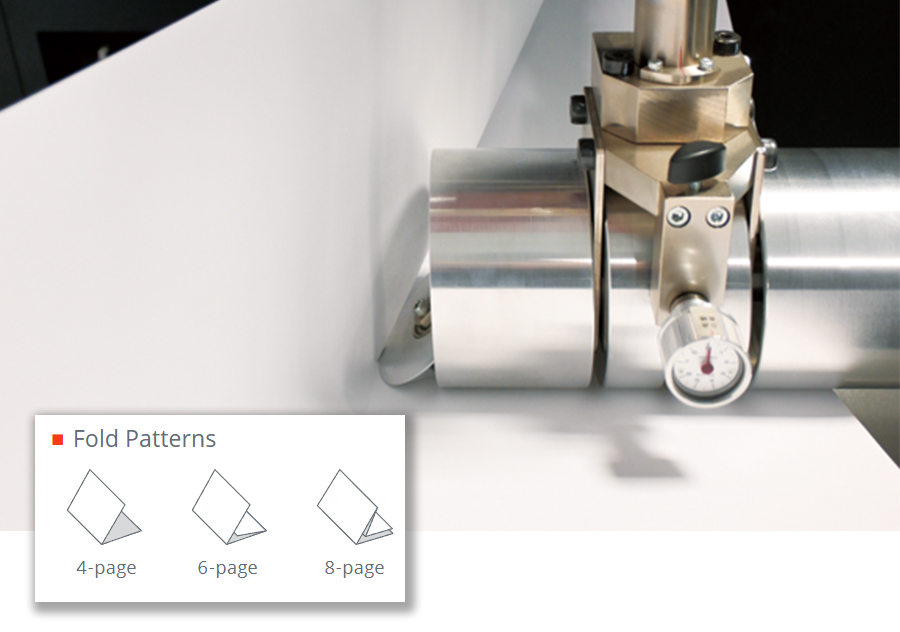

| Sheet Weight Range | Normal Paper: 60 to 157 gsm Coated Paper: 60 to 157 gsm Limitation due to folding pattern 4 pages (half fold) : 60 to 157 gsm 6 pages (letter fold)* : 60 to 100 gsm 8 pages (double parallel fold) : 60 to 80 gsm *Z folding is not possible |

| Book Block Size | Width: 109.0 to 292.1 mm or 4.30” to 11.50” Length: 152.4 to 320.0 mm or 6.00” to 12.59” |

| Stack Height | Max. 80 mm or 3.14” *This value indicates the height of the stacker, not the book block thickness. The stack height varies depending on the signature pattern, sheet type, and the ambient temperature and humidity conditions. |

| Production Cycle | Max. 800 stacks per hour |

| Processing Speed | Min. 30 meter per minute Max. 160 meter per minute *This value indicates the belt transport speed, not the production speed. Productivity is determined by the delivery cycle and varies depending on the signature pattern, sheet type, ambient temperature, humidity, and glue condition. Check the conditions before setting the processing speed. |